A swimming pool pump motor is one the largest consumers of household energy. In fact, they are second only to air conditioners. A variable speed motor is a simple solution for that constantly increasing power bill. Here are 5 reasons to get a variable speed pool pump motor.

Energy Efficiency

Kicking off our top five list is energy efficiency. Variable speed (VS) motors can use 50% to 75% less energy than traditional single speed motors and get the same job done. Even though there are sufficient data and customer feedback to support that claim, there are still skeptics. Those skeptics will allege that replacing the current single-speed motor with a lower HP single speed motor can produce the same savings. They are not taking into consideration the design of the variable speed motor and the Pump Affinity Law.

Most variable-speed motors, like the Century V-Green, are considered permanent magnet motors. Thanks to the magnets working to spin the rotor, efficiency is improved in the VS motor. Single-speed induction style motors lose efficiency because additional electricity is required to activate the magnetic field in the rotor. This means that if the same flow rate is needed, a variable speed motor will operate more efficiently and draw less power. Wait, it gets better!

Unlike single-speed motors that can only operate at maximum flow rates, the variable speed motor can slow the water flow and maximize savings. To comprehend what these savings can be fully, it is important to grasp the Pump Affinity Law. This law is used to demonstrate the relationship between motor speed, flow rates, and energy consumption. Essentially, it states that the power consumption drops dramatically as the motor speed and water flow are decreased.

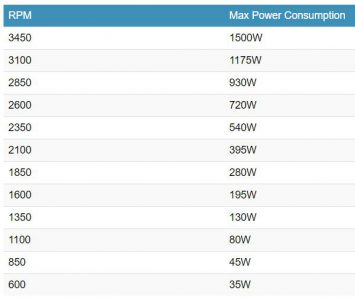

To better illustrate the Pump Affinity Law, we have put together a chart showing the decrease in power consumption based on RPM setting. The numbers reflect a Century V-Green 1.65 HP motor paired with a 1.65 total HP impeller.

Durability

Variable speed motors are totally enclosed and fan-cooled. The enclosed design protects the internal components of the variable speed motors from environmental elements. On the other hand, single and dual-speed motors are standard induction motors. Vents on the induction motors can allow water, and sometimes critters, to enter and cause damage.

Furthermore, because the variable speed motors run at lower speeds and because they are fan-cooled, the motors stay much cooler. This will aid in preserving the bearings and motor windings. Ultimately, these design differences allow the variable speed motor to have a longer life.

Easy Installation & Programming

Installation of the variable speed motor is the same as a single-speed motor. All of the original pump components can be transferred to the VS motor. This excludes the pump seals which should always be replaced when a new motor is installed. The wiring from a single speed motor is also transferable. The same three lines that were used for the single-speed motor can be used to supply electricity to the VS motor.

Once the motor is installed, it needs to be programmed. Since every pool is different, the programming is not standard. The speed settings will have to be dialed in according to the equipment’s requirements. This will require experimenting with running the motor at different speeds. Once the minimum operating speeds have been determined for each piece of equipment, the run times can be set.

Keep in mind that the items like automatic cleaners and water features do not need to run the entire time the pump is on. It is normal to have those items running only an hour or two a day. A low RPM can be used to circulate the water the rest of the time. As stated before, running the motor on lower speeds generates the greatest savings.

Additional Resources – Poolside Repair: How to Install an Energy Efficient Motor

Remote Monitoring

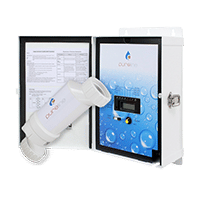

Until recently, the ability to monitor the pool system remotely required an elaborate control system. Century V-Green variable speed pump motors now have wireless capability when combined with the VLink interface. Once the VLink is connected to the home’s wireless network, the pump can be controlled from any smart mobile device.

Pool owners can program, monitor and adjust settings anytime, anywhere. Plus, the VLink app displays live energy consumption and delivers the exact operating cost.

Quiet Operation

Concluding our top 5 reasons to get a variable speed motor is noise or a lack thereof. As mentioned before, VS motors are totally enclosed. This means that most of the noise generated is muffled instead of being released through vents like the induction-style motors. While operating at a low speed, it’s hard to tell if the motor is running. Actually, the variable speed motors running at a high speed are noticeably quieter than traditional single-speed motors.

Leave a Reply