Reading, understanding, and diagnosing Pentair MiniMax NT heater error codes are understandably confusing for the typical pool owner. In fact, it can be very difficult for any pool owner regardless of his/her skill set. It is simply the nature of the beast.

Troubleshooting and diagnosing technical issues can be more difficult online. It seems like a catch-22 to me, though. The Internet allows us to have instant access to tons of information right at our fingertips. Still, with all the information available, sometimes it can convolute the information and cause even more confusion. It is very similar to when you are trying to diagnose why your back is hurting. Twenty minutes into reading WebMD and you are halfway to diagnosing yourself with cancer. It can be a very slippery slope.

Diagnosing technical issues on older products is in it’s own league. User manuals and technical documents weren’t as informative for the reader like they are now. Today, manufacturers are more tuned in to their customers’ needs. Although the Pentair MiniMax NT heater was manufactured over a decade ago, we still run into pool owners who still own and love their heater and would prefer to fix the issue than purchase a new one.

As I began my research on the Pentair MiniMax NT error codes, I immediately noticed the lack of resources for this heater. Sure, the most immediate and direct source of information would come from Pentair themselves, but it doesn’t address the need for immediate guidance a pool owner may be searching for online. If you have a Pentair MiniMax NT and are experiencing technical issues, this blog is for you.

One of the reasons it is so hard to diagnose technical issues online is because every pool and every heaters are different. Tiny variables in the installation of the heater can attribute to why one thing can fix an error code for one pool owner but not the other. In some instances, the cause of an error code can be unique for the pool owner and their set up. With that in mind, we gathered as much information and attempted to include all the different reasons why an error code may present itself. Not every recommended solution will work for every scenario. In the event that our error guide does not cover your particular issue, or simply does not rid your error codes, we recommend contacting Pentair directly at 800-831-7133.

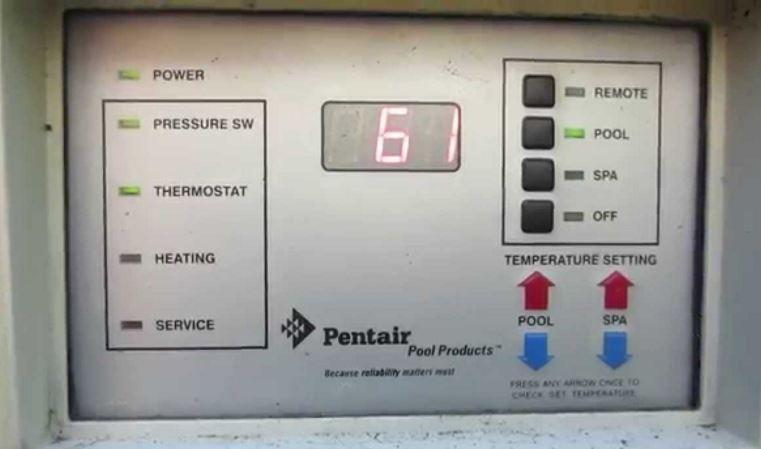

LED Indicators

There are nine lights that can be seen from the front of the control panel. Five are system indicators and four are mode indicators. If something should go wrong, the lights will aid in troubleshooting the problem.

An additional four lights can be seen after opening the control panel. These four lights are diagnostic indicators for the service technician to troubleshoot the system. Before we dive into the error codes, let’s explore the five system indicators.

I. Power

This light indicates 24VAC power is being supplied to the control circuit. It should remain on at all times. If this fails to light up, so will the remaining indicators. This can mean 2 things:

- External power to the heater is disconnected. Check service panel circuit breaker, or fuse.

- Transformer has failed.

II. Pressure SW (Water Pressure Switch)

This light indicates the circulating pump is running properly. The light will stay lit when the Spa/Pool Selector switch is on. If it fails to light up, the pump may have lost its prime or your water flow is restricted. Make sure to:

- Verify if the pump is primed.

- Check water flow restriction. There may be a closed valve or a clogged filter or pump basket.

III. Thermostat

The ‘Thermostat’ light is an indication that your water’s temperature is falling before the set point. This causes your heater to fire in order to maintain the desired water temperature.

IV. Heating

The ‘Heating’ light is on any time the thermostat has signaled a call for heat. This initializes the ignition safety circuit. The heating light is an indication that your unit successfully fired the main burners and will stay on until the water reaches its desired temperature.

V. Service

The ‘Service’ light is off during normal operation of the heater. This light will only come on if a problem with a control has occurred, or when the heater is first firing.

MiniMax Error Code Guide

The Digital Display Temperature Controller (DDTC) display contains three LEDs with a decimal point between the first and second. This display is also used to display an error code if there is a failure within the heater control system or a DDTC internal fault. The DDTC will display the actual temperature or the set-point temperature. When the DDTC detects an error, the display will show Exx, where Exx is the error code of the DDTC fault. Codes 1 through 9 indicate a “soft lockout”error which means the heater will resume normal operation and restart immediately after the errors are fixed. Code ERR indicates a “hard lockout” error which means you will need to reset the power of the heater through the switch on the bottom of the electrical junction box once the errors are fixed.

E01- System Low Voltage

The ‘E01’ error code indicates system low voltage. What exactly triggers a low voltage? The E01 error can be caused by a few things:

- Incorrect incoming power

- Heater connected to the wrong voltage

- Transformer not outputting the correct voltage

Solutions

Check the voltage going into the heater. If the voltage is correct, the issue may be the transformer.

E02- High Temperature Limit

The ‘E02’ error code indicates that the high limit sensor has tripped. A “High Limit” is a safety device that opens the electrical circuit and shuts off the heater based on a water temperature set point within the “High Limit Device”. The MiniMax NT heater contains (2) high limit devices which are located on the main inlet / outlet header. One senses the inlet water temperature and the other senses the outlet water temperature. To verify, you will need to trace the voltage through the sensor loop to find where it is stopping and which sensor could possibly be at fault. Specifically, you will need to check the voltage on either side of the high limit switch.

An abrupt shut off, such as an electrical shortage or lightning, can also trigger the E02 error code.

Solutions

- Verify the voltage going through high limit sensors. Replace if necessary.

- Verify if the heater was wired correctly

E03- Thermal Fuse is Open

The E03 error code indicates that the thermal fuse is open. The thermal fuse/cutoff is a safety device that is held together by wax. Upon detection of excessive heat within the inner front panel, the fuse will open the safety circuit causing the shutdown of the heater. It’s main job is to keep the heat source from hurting the heater. In short, if the thermal fuse is open, you may have fire backing up into the heater outside the fire box.

Solutions

- Examine the thermal fuse. Replace if you see any sign of wear and tear or defect.

E04- Fan Failure

The ‘E04’ error code is an indication that the fan, or blower, has failed. Sometimes the signs are apparent like simply hearing unordinary noises coming from the fan. Or, sometimes it can be misconceiving. The blower may turn on and the heater may fire up for a few seconds, but will turn back off within a few seconds.

Solutions

A couple of things can trigger the E04 error code that you should check for:

- A possible bad air flow switch

- The tube in the air switch (check if it is chewed up or not connected)

- A bad blower motor

E05- Ignition/ Flame Failure

The ‘E05’ error code indicates that the ignition has failed. In many cases, the heater may fire up and heat for a few minutes, but shorten out. Typically, this is caused by a bad igniter, but not always. This also frequently happens to pool owners who have not fired their heater in months. The E05 error code is a pretty general failure code and could be generated for many reasons.

Solutions

A few different possibilities will cause the E05 code. Make sure you check:

- Igniter- It’s possible that the igniter is bad or just a little rusty. Try cleaning and restarting the unit. You may need to replace it altogether.

- Burner assembly- Check for rust debris from the base heat shield louvers. They tend to rust.

- Bad sensor- Check the sensor to ensure it’s not damaged in any way. Try cleaning and restarting unit. You may need to replace it altogether.

- Intake/outtake- Check the intake and the outtake venting for obstruction. This will prevent the igniter from starting.

- Control board- You may want to check the lights on the back of the control board. There are indicator lights in the back of the board that should help you further diagnose the problem. Pentair recommends calling a certified Pentair Service Technician for troubleshooting the board.

E06- Gas Main Valve or Module Failure

Although there is not much information for this error code online and we are currently waiting for an explanation from Pentair themselves, I did find some information in the manual. If you get an E06 error code, you should check:

- Fuel supply

- Thermal regulator

- Correct orifices

** If you see the ‘E06’ error code, we recommend you contact Pentair directly and allow them to troubleshoot the unit with your over the phone.

ERR- ERROR

Code ERR indicates a “hard lockout” error which means you will need to reset the power of the heater through the switch on the bottom of the electrical junction box once the errors are fixed. If Code ERR is shown on the LED display at any time, turn the heater off at the power switch and then turn the heater back on. If the error code is still displayed, call a certified Pentair Service Technician for repair.

We write blogs like this one to help pool owners save as much money as possible. Why pay someone to do something you could have easily done yourself? It makes little sense. What does make sense, though, is not biting off more than you can chew. If for whatever reason you do not feel comfortable doing anything with your unit, don’t. Heaters are expensive pieces of equipment and sometimes the pool owner can do more harm than good. A good rule is, when in doubt- give Pentair’s technical support a call. They will troubleshoot the heater with you over the phone and help come up with viable solutions.

Leave a Reply