Valves are an unsung hero of pool equipment because they allow us to control the flow of thousands of gallons water with the twist of a handle. However, the only time you most likely wondered how they worked was when they didn’t work. These pieces of metal and plastic have various designs and applications suited for specific jobs, and the key is knowing when to use which valve. This walk-through of the various types of swimming pool plumbing valves should give you the knowledge you need. Let’s begin!

Check Valve

Check valves are dandy pieces of machinery that serve the dual purpose of monitoring the flow and preventing the backwash of water. The check valve’s two most common designs are the spring and flapper regulated valve. Both do the same basic job, but just differently.

Flapper Check Valve

Besides the funny name, I like this valve because it reminds me of a one-way doggie door. The spring loaded flap is tensioned to one port of the valve body. The flap opens as water pressure rises and will remain open as long as the flow is at proper rates. The flapper style has a sizeable viewing window for easy inspection.

Spring Check Valve

The spring check valve uses a unique in-line plunger to affect a sleek and effective design. The valve is plumbed with the plunger facing the flow of water. As your pump builds pressure, the plunger will open allowing water to pass. The spring check valve is available in various spring tensions so a user can adjust the flow needed to open the valve. Spring check valves are sold with varying spring tensions that allow you to determine how much flow it takes to open the valve.

Most common spring tensions:

- ½ lb.

- 1 lb.

- 2 lb.

The spring check valve is available in an opaque or clear housing. The latter allows you to determine flow and valve function at a glance.

When to Use It

The check valve’s intended purpose is to prevent backwash. For those of you who have never shared a soda with a friend, backwash is when a pipe loses pressure causing the contents of the pipe to recede to the source. Or, if you want a more dramatic explanation: the fluids withdraw from WHENCE they came! Not only is this bad for your fountain drink, but it is terrible for pool equipment too.

Most pools use a chlorinator system (salt or tabs) that is plumbed last in your series of filtration equipment. This placement puts the chlorinator directly after your pool heater, heat pump or chiller and squarely in the crosshairs of your chlorinator’s super chlorinated backwash. Chlorine in its concentrated form is super corrosive and damaging to metals, especially the fragile conducting metals found within the heating equipment. The only thing protecting your metal parts from destruction is the dilution of chlorine once it shoots back to your pool. Dilution and the process of killing microbes deplete the strength of chlorine by the time it cycles back to your filter equipment.

When your pump turns off, the water in your chlorinator may recede to your pool heater where it will sit for hours until your pump restarts. During that time, the super chlorinated water has time to gnaw, chew and munch away at your copper heat exchanger. The cause and effect of that process is a very expensive heat exchanger replacement sooner than necessary.

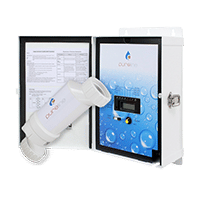

Also, check valves (usually the spring type) are used as bypasses to aid in heating and salt chlorinators. Some manufacturers suggest a bypass to your heater’s plumbing to slow the flow of water through the heat exchanger. The lower flow keeps the water in contact with the heat exchanger for longer that allows for a more efficient transfer of heat. The same logic is used in salt chlorinators and the titanium cell plates, most notably on the Autopilot systems that include a bypass manifold, seen in the. The bypass manifold diverts flow equivalent to 20 GPM (or so) through the cell, any flow above that tolerance will open the check valve at the bottom of the loop, bypassing the cell. The slower flow allows for a thorough chlorination of the water and prevents undue wear on the cell’s plates.

Check valves are normally installed horizontally, and a few can be installed vertically. Check the manufacturer’s installation guide if you need a valve for vertical installation.

Shut-off Valves

Shut-off valves are used to stop the flow of water through one or more pipes completely. Thus the name shut-off valve. Valve manufacturers are not very inventive when it comes to names, but they are crafty when it comes to design. So, let’s dig in.

Diverter Valve

The diverter is the workhorse of the pool valve family. If you have an in-ground pool, there is a high probability you have one of these bad boys on the plumbing system. These valves contain a diverter that slides over the port holes to close it or to the side to allow full flow.

Application:

- They are available in a two or three port version.

- The two-port is essentially a 1-in and 1-out that allows the user to shut down flow completely.

- The three-way or T-style has one in-port and two out-ports that allow flexibility to isolate flow to one port or shut off flow to both out, but closing the inlet.

When to Use It?

Diverter valves can be used on PVC plumbing for in-ground or above ground pools. They can be fitted vertically or horizontally. There are two types of diverter valves – the positive seal, and non-positive seal.

- Positive seal – Completely seals the valve opening preventing any seepage. The diverter gasket is more robust and protrudes from the face of the diverter to create a firm seal.

- Non-positive seal – Allows some water to pass through the diverter when closed, making it not ideal for standard plumbing use. Non-positive valves are normally found on systems with solar heaters so water can drain from the solar panels even when a valve is set to “CLOSED”.

Gate Valves

Gate valves are a simple on/off flow regulator used mainly on above ground pools, but they can be found on older in-ground installations. These valves should not be used to throttle water flow, but only as a purely on/off regulator. The valve’s design consists of the body and the internal gate, with the handle and stem.

The gate is a wedge or circular plate that is risen or dropped to regulate the valve. Gate valves can serve a dual purpose of an adapter and a valve. The in the section shows the various port style combinations available. The valve can connect threaded PVC to a hose, slip PVC to threaded, and can even have a union adapter on one side with your choice of connection on the other.

When to Use It?

Gate valves are installed on above ground pools for their ability to shut off hose or PVC piping while filtering equipment is serviced.

Ball Valves and Butterfly Valves

I mention these two in the same breath because they do the same task in similar ways. The ball and butterfly valves both use a spinning element/insert to stop or release the flow of water with a quarter turn of the handle. The ball valve uses a metal (usually copper) sphere with a cored center to allow water through.

Butterfly valves use a spinning paddle plate to adjust water flow. A quarter turn of the handle spins the paddle sideways releasing the flow. Butterfly valves are unique in the sense that their element remains in the direct path of flow at all time. The gate, diverter and ball valves element for stopping water only in the path of water when the flow is being actively blocked.

When to Use It?

Butterfly Valves are most commonly found in commercial pools whereas ball valves are used as shut-off valves on small water features.

Leave a Reply