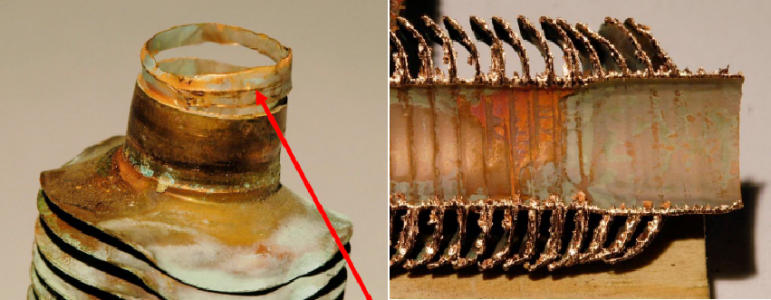

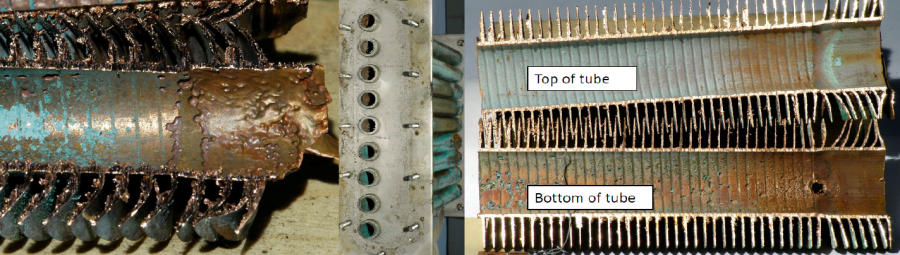

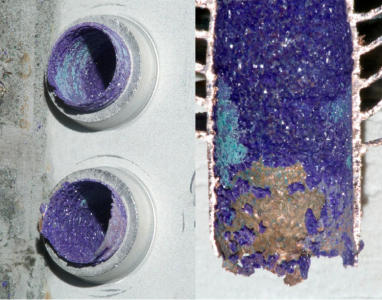

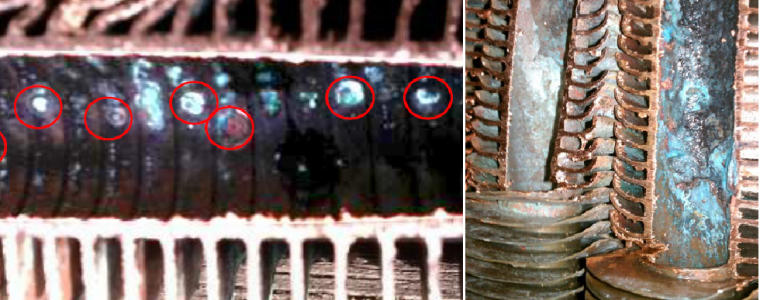

Picture this nightmare scenario: You try to fire up the old gas heater, but your pressure is spiking, the water is lukewarm, and you might even see a growing creek of water streaming from your heater cabinet. If this has happened to you, you know these are all symptoms of a failed (or about to fail) heat exchanger.

But we are here to avoid this scenario. Let’s try to keep your heater running as best as it can and for as long as it can. Let’s discuss the things you absolutely want to avoid exposing your heater to.

What is a heat exchanger?

A heat exchanger is a series of metal alloy tubes designed to transfer energy from a heat source into the water flowing within to warm or cool it.

Heat exchangers can be made of three different materials: copper, cupronickel, and titanium. The most common type of heat exchanger is copper. The soft metal allows for the most efficient heat transfer of the three metal types. The main drawback of copper is its fragility in diverse water conditions.

Its heavier duty cousin, cupronickel, is also used in gas heaters and can be safely used in more adverse water conditions and salt pools. Titanium heat exchangers have exclusively been used in heat pumps. This is because they are the most resilient of the three exchanger materials.

Plumbing

- Install a corrosion-proof check valve Harford Loop between the heater and chlorinator

The check valve is a device that opens when water is moving but shuts when the flow halts. The sprung flapper that closes when the water stops flowing prevents water from backwashing and settling from the chlorinator into the heater. A Harford Loop does the same job as a check valve, namely preventing backflush of liquid by creating a rise high enough to stop any backflow.

As you may have already read in our article “What order should I install my pool equipment in?”, the chlorinator should always be installed after the heater. Installing the heater and chlorinator in that order helps prevent undiluted chlorine from rotting your exchanger. Unfortunately, if your pump stops, the water will stagnate and even backwash from the chlorinator and settle in the exchanger.

Chlorine

- Residual chlorine levels should not exceed 5 ppm

Chlorine is fantastic at killing bacteria, microbes, and any other undesired amoeba in your pool. But those great sanitizing powers have the adverse effect of corrosion. Prolonged exposure to high concentrations of Free Chlorine levels above 5 ppm will cause deterioration leading to premature failure of the heat exchanger.

Don’t worry, though; you can still use pool shock, which is likely to take your Free Chlorine levels above 5 ppm. Pool Shock is a super concentrated form of chlorine, but due to its lack of cyanuric acid, the effect of the shock dissipates quickly.

Balancers: pH, Alkalinity, Calcium Hardness

- Pool pH level between 7.4 and 7.8 is optimal

- Total Alkalinity between 100 and 150 ppm

- Calcium Hardness 250 to 400 ppm

These balancers need to stay within the specified ranges, or copper heat exchangers can begin to show signs of deterioration within a few months. However, keeping them within these ranges should be relatively easy as they are the foundation of pool water chemistry.

How to Balance Your Pool Water

Water Chemistry For Saltwater Pools

Total Dissolved Solids (TDS)

- TDS below 3000 ppm – TDS in salt chlorinated pools can be as high as 6000 ppm

Total dissolved solids (TDS) is the measurement of anything that has dissolved in your pool water, e.g., salt, calcium, organic material, and balancers (i.e., soda ash, sequestered metals.) Essentially, it is a measurement of how saturated your water is. That saturation of charged minerals in the water aggressively strips copper tubes.

If your TDS levels are high, drain a portion of your water and fill it with fresh water.

Miscellaneous

- Heater and equipment are equipotential bonded

- Never put chlorinated tablets in the pool’s skimmer basket

- The salt level should not exceed 4500 ppm

- Little or no copper in the water (.2 to .5 ppm would be considered high)

Bonding your pool equipment is a must to protect your equipment and swimmers. Bonding the pool and its equipment prevents stray voltage from zapping anything or anyone. If you are unsure what bonding is or how to do it, give this guide a read: How To Add a Line to the Pool Bonding Wire.

Never ever put chlorine tablets in your pump or skimmer basket. This tip is not just for systems with heaters; any pool owner should follow this rule. Chlorine is very corrosive, even when you are diluting it to a level as low as 5 ppm. When you place your chlorine tablets in the skimmer or pump basket, you are mainlining undiluted chlorine directly into your pump, filter, and heater internals. That chlorine will not only rot your heat exchangers but also make brittle and decay your equipment’s plastic internals.

High salt levels will lead to excessive scaling that causes blockages in the copper tubes of the exchanger. Keep your salt level within the 3000 – 3500 ppm, which is the sweet spot for most of the salt chlorine generators on the market.

Thank you to Raypak for providing the picture of examples of the after-effects of bad water chemistry.

Leave a Reply