It’s really frustrating when you purchase an expensive item, install it, and it immediately malfunctions. For most pool owners, troubleshooting single-speed pumps can be tricky and annoying and time-consuming and… Well, you get the point. Now, imagine the frustrations you experience while troubleshooting your dual speed pump. Over the last few months, we’ve come across customers experiencing problems with their dual speed pump. The common complaint is, “My pump runs on low speed but not on high speed.”

As the heart of your pool system, it’s absolutely necessary to keep your pool pump operational. The purpose of this blog post is to help pool owners determine why their dual speed pump runs on low speed but not on high speed.

Can I Run My Pump Only On Low Speed?

What happens when you purchase a new dual speed pump, install it, and it immediately gives you problems? Your pump operates smoothly on low speed but fails to function properly at high speed. What is the solution we hear from our customers the most?- Run it on low speed forever and ever. If that works for you- great. Odds are, though, it won’t work for most pools. Serious question- why would you sacrifice a product you just spent hundreds of dollars on?- You shouldn’t!

So, can you run your dual speed pump on low speed only? – Yes, but here’s why you probably shouldn’t.

If you cannot operate your pump at high speed, you may lose the ability to control your waterfalls, pop-up heads, spillovers, jets, and bubblers. Water features typically require more gallons per minute (GPM) than what the low speed on pumps produce.

We also recommend checking the minimum GPMS your heater and salt chlorine generator require for operation. For most, the minimum is around 35 GPMS. If on the low speed your pool pump is pushing less than 35 GPMS, then you will lose functionality of your salt system and heater.

Lastly, depending on the size and shape of your pool, running your pump solely on low speed may not provide enough circulation. Or, it may provide just enough circulation if you’re running your pump all day.

Why Isn’t My Pump Running On High Speed?

Before we can get into why your dual speed pump isn’t working on high speed, we first need to determine when it stopped working altogether. Was your pump running on both low and high speeds initially? Or, did the problem arise immediately after installing your pump?

Recently Installed Pumps

If you just installed your dual speed pump and realized it isn’t working on high speed- don’t fret. There’s a possibility that you simply installed your pump incorrectly.

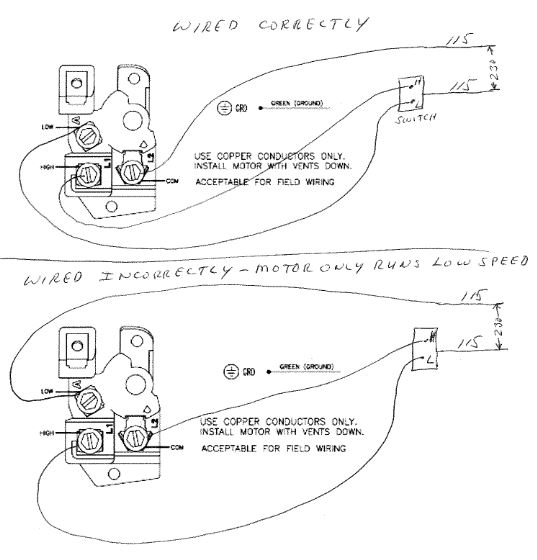

Below is a diagram of the correct and incorrect wiring of a DS pump.

In the example above, the motor will only run at low speed when switched to high speed. If the wire from the H position on the switch is connected to HIGH and the L is connected to COM, the motor will only run on low speed. In most cases, even when installed incorrectly, there shouldn’t be damage to your motor nor will it trip your breakers.

If you’re not familiar with wiring diagrams, it can seem like another language. We never recommend pool owners to complete tasks that they are uncomfortable performing.

Here are a few other helpful resources for wiring a dual-speed Pump:

How To Install a 2 Speed Motor and T106 Timer

How To Wire a PE154 Digital Timer to a 2 Speed 230v Motor

How To Wire the 1011431-001 Toggle Switch to a Century STS 2 Speed Motor

How to Wire the 18313301 Switch to 115 Flex-48 2 Speed Motor

How To Wire the 2512558-001 Toggle Switch to a Century 56Y 2 Speed Motor

Troubleshooting Two-speed Motors That Have Been Working

If your motor was running properly on both high and low speeds, but now it will only run at low speed, the issue is definitely related to the motor or control. On high speed, there is the main winding and a phase winding with a run capacitor. If any of these components aren’t functioning, the motor will not start. The first and easiest thing to check is the capacitor. If the capacitor checks okay, then the likely cause of the problem is a shorted phase winding.

Unfortunately, if the winding is bad, it cannot be replaced and you will need to replace your whole motor.

Windings and Two Speed Motors

Certain types of two-speed motors actually have two separate windings in one housing. Most have a separate main and phase windings. Still, a few two-speed designs only have a low-speed main winding. This design always starts at high speed and switches to the low speed run winding within a couple of seconds. This motor was a less expensive design since there was no low-speed start windings or a start capacitor.

Remember…

Any of the troubleshooting guides that pertain to single speed motors can be applied to dual-speed motors. Remember, if the high-speed option isn’t working and you recently installed your pump, odds are you wired it up incorrectly. However, if the high speed stopped working after years of operation, check the capacitor and phase windings. It’s easier to replace a capacitor than a phase winding. Usually, pool owners purchase a new motor once the windings are bad. Lastly, if you’re having difficulties reading or understanding your wiring diagram, give us a call and speak to one of our technicians.

Leave a Reply