Good question; strike that, great question! This topic is brought up quite often by puzzled pool owners presented with a rat’s nest of pipes, elbows, valves and pumps. The state of some pool plumbing systems makes you wonder if they charged by the hour or by the pipe. The maze of PVC and excessive valves causes an issue when attempting to find the source or outlet of water flow.

Another common reason we have trouble identifying a pool diverter valve’s function is the label may have bleached out or fallen off. These are natural occurrences that we normally do not think about until we are squinting to read faded print on a baked label. But we are here today to let you know a little trick on identifying the function of your valve in both of these cases.

We call it the “Trial and Error Method”! Ok it is nothing new but it is the simplest way of getting to know your plumbing system. We will walk you through the steps so you no longer stare at your pool diverter valves with deep ponderings of what they may do.

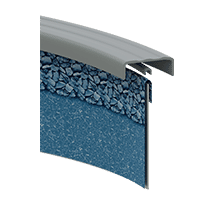

Before we jump in, let us first illustrate how the common two-way and three-way valves operate. The two way valve has two ports; when open, the handle is perpendicular with the pipe and when closed, it is in line. For three way valves: the valve is open when the handle is over the middle port. The three way port can close in three directions; whichever port is opposite the handle position, that will be the closed port.

Part One: Pencil & Paper

The simplest of the steps; we will be using this to number our valve and plot out the water entry points throughout our system. Mark each pool diverter valve with a number and sketch your pool marking the inlets with a letter. As we are checking off each valve, we will mark down which valve goes with what inlet with this simple number-letter scheme.

Make two separate categories: Suction Side and Pressure Side. The suction side will be focusing on the valves before the pump and pressure side will be for valves on the return lines.

Part Two: Find Your Water Inlets

As mentioned in the previous step, we want to locate each inlet before we start fiddling with valves. These entry points include return lines, waterfalls, laminars, spa jets or bubblers.

Step 3: Turn on the Pump

Step 3: Turn on the Pump

To identify the direction of water flow, the pump will need to be on while we open and close the valves. Unlike a multiport valve, when we change positions on a diverter valve we do not need to turn off the main pump. As we go through our progression of valves always make sure at least one outlet valve is open before closing the previously tested. This process will prevent a dangerous level of back pressure from building within the pipe. Back pressure can damage your pool equipment or swimmers. The same rule applies to the suction side of pumps; make certain at least one of the inlet lines is fully open to prevent the pump from running dry.

To help in this process, I would suggest having a helper who can check for water flow at the specified water inlet while someone is progressing through the valves. This will cut down on the running back and forth between the pool equipment and the pool.

At this point we have marked our valves and water inlets and have the pump running; now we can start cycling through the valves to determine the location of their output.

Part Four: Turn on Individual Valves: Check Flow

Pressure Side

Open the valve we have designated as Valve One, and close all the other valves. While the pump is running, check each of the known water  inlets for flow. We can do this by sight or by hand. If the port is below water it may be hard to determine if water is flowing by sight alone. Match the designated letter of the inlet with the valve number that is open. Follow these steps until all valves and inlets are identified.

inlets for flow. We can do this by sight or by hand. If the port is below water it may be hard to determine if water is flowing by sight alone. Match the designated letter of the inlet with the valve number that is open. Follow these steps until all valves and inlets are identified.

Suction Side

Most pools have a series of skimmers and main drain lines that consolidate to single line as it reaches the filter pump; in that case we would work reverse the flow of water and check valves starting with the last valve before the pump’s intake port.

This example shows a three way valve where one side controls the main drain and the other side the skimmers. To determine the water flow, close the one side of the valve as the pump is running. Visually inspect the skimmer(s) for water flow and the telltale swirl of draining water through the basket. If the skimmer is draining water then the main drain is closed, and vice versa. Make the necessary mark on our valve checklist.

On the chance there are multiple main drains controlled by separate valves or a three-way valve, identifying becomes a little trickier. We need to be able to determine which valve is open and which is closed and that is not something we can visually inspect from the deck. For those of you reading this in cold weather who do not wish to take multiple dips in the pool, there is a easy trick to determine flow. Take some food dye and drop a few teaspoons into the water. As the dye sinks to the bottom the active drain will draw it allowing us to visually check which drain is open for our checklist. Success! This trick is also used in finding leaks in pool wall and floors.

**DO NOT STICK YOUR HAND IN SKIMMER OR ON MAIN DRAIN TO CHECK FLOW**

Part Five: Buy a Label Maker

Label each diverter valve with the Name/Description of each inlet that it controls; this will prevent us from doing this again. Once the valves are labeled, take a picture of the system and email to yourself or store it somewhere safe. Just in case the labels you made fade away or fall off, you have a pipe map at your fingertips.

Thank you for sticking around and reading my blog. If you have any further questions, please give our techs a call at 877-372-6038. We are glad to help!

Leave a Reply