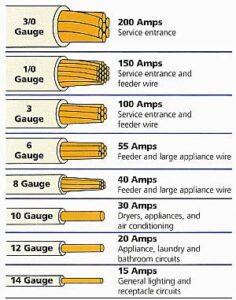

An important part of a new pool pump installation is the circuit wire used for the power source to motor connection. To make your pump run as efficiently as possible, your pump motor needs enough juice too. In this article, we’ll cover the basics of selecting the correct wire for your motor.

What to consider when picking the wire gauge?

Material

The one and only choice for a wire material for a pool pump is copper. Copper has a lower resistance than aluminum which is the other common wire choice. Copper’s low resistance lessens voltage drop.

Length of run

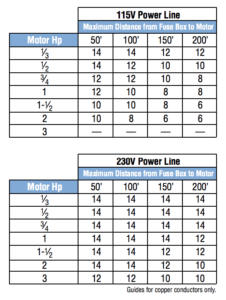

This refers to the length of wire needed to span from the power source (usually the circuit-breaker box) to the pool pump motor. The longer the wire, the thicker it needs to be. Remember that thin wire has a higher resistance causing higher voltage a drop which leads to an overheating motor

Pump Horsepower & Voltage

The higher the motor horsepower, the more electricity it requires. The voltage being supplied to the motor plays a factor because of the number of hot wires used for 115 and 230. A 115-volt circuit has only one hot wire carrying, meaning the amperage is carried solely through that wire. This means that the wire has to be thicker to avoid overheating. A 230-volt circuit has two hot wires carrying voltage, splitting the amperage draw evenly, allowing a smaller gauge to be used.

Wire Gauge Chart

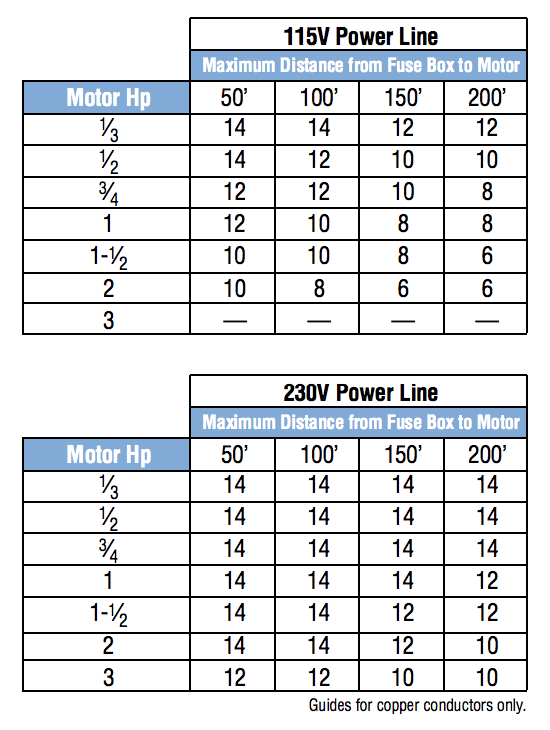

This wire gauge chart provided by A.O. Smith:

Why is wire gauge important?

For your pool motor to generate power (watts), it requires two things from your electrical source – amperage and voltage. The circuit bringing the amperage and voltage to your pump needs large enough wires to accommodate both of these elements for the motor to operate efficiently. The motor is shooting for its wattage goal, and can harm itself in trying to reach it.

P (Watts) = PF(Power Factor) × A (Amps) × V (Volts)

If the circuit wires are too narrow, the motor usually sacrifices voltage to overcome the bottleneck in the wire. The motor, in turn, draws more amperage so that it can meet its power demands. Unfortunately, the higher amps create more heat, stressing the motor and lowering its life expectancy.

Do you have any topics you’d like covered in our Pool Care Basics series? If so, feel free to leave a comment down below with any questions you’d like answered.

Leave a Reply