For a piece of equipment that is not electrical, digital, or highly complex, a pool filter can still cause a great deal of pool owner stress. You might be surprised how many questions we field regarding what is essentially a big tank that water passes through. But since that tank is so vital to the operation and safety of your pool, I wanted to share the some of the most common issues our techs encounter and how you might troubleshoot some basic problems.

#1 The Spider Gasket

Inside the multi-port valve on DE and sand filters, you will find this gasket which somewhat resembles a spider web, featuring a small center ring and spokes (typically 4 or 5) that connect to a larger outer ring. For a small, simple part, it can be the source of quite a few filter headaches. Signs of a worn or damaged spider gasket include leakage around the valve or water coming out of the waste line even though valve is set to “filter”. Damage to this gasket is commonly caused by moving the valve handle while the pump is running.

If you need to replace the spider gasket, look at the valve body itself (not the filter tank) for a model or part number. With a valve model number, the correct gasket can usually be cross-referenced. It is worth noting that some manufacturers include the spider gasket only as part of the diverter. In this case, you would need to purchase the entire diverter assembly. If you are unfortunate enough to find yourself in this camp of filter owners, you will want to compare the price of the diverter vs a completely new valve.

#2 True Grit

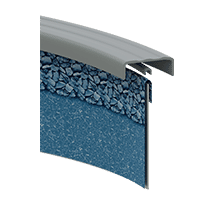

Probably the most ironic of filter problems is sand or DE powder flowing back into the pool. For sand filters, one or more cracked laterals or a broken standpipe is typically the culprit. Replacement laterals can be purchased individually or as part of a standpipe assembly. The standpipe is available separately also, if you determine all of your laterals are in good shape.

For DE filters, you are usually looking at worn grids that have developed tears. While checking the grids, also inspect the standpipe o-ring for wear and tear. Another cause of DE in the pool is simply adding too much DE powder when recharging the grids. Be sure to follow the manufacturer’s instructions; in the absence of an owner’s manual, a general rule of thumb is 1 lb of DE per 10 sq ft of filter area (this refers to the square footage of your filter, not your pool).

#3 Under Pressure

Feeling the pressure of pool ownership? Then you and your filter might have something in common. Some filter problems are caused by excessive pressure build-up inside the tank. High pressure can be caused by having a filter that is undersized for the pump; this means the pump is pushing more gallons per minute than the filter is designed to handle. Another cause is simply a dirty filter with cartridges that need to be rinsed, or sand or DE that needs to be backwashed. If after cleaning, you are still faced with high pressure, there could be a clog in the plumbing lines.

High pressure can cause laterals to crack and leak sand into the pool. It can also be the reason for a cracked tank or even more dramatic, the filter lid blowing off.

#4 Feeling a Little Low

As mentioned above, high filter pressure is a problem but so is low pressure which usually indicates some obstruction of the water going into the filter. This can negatively impact pool circulation. First step – check your pump strainer basket and impeller. If either one is clogged with leaves and other debris, clean them out to increase water flow.

Low pressure can also be linked to the pool skimmer which could have a clogged basket or a weir stuck in the open position (the weir is the flap on the skimmer that sways back and forth). Reduced water levels can also cause low pressure.

It’s worth noting that a broken pressure gauge can give a false reading, high or low. Check to make sure the gauge needle returns to zero as it should when the pump is off.

#5 The Replacements

All your filter might need is new cartridges or grids but good luck trying to figure out which ones you need. This is a very common conundrum. Frequently, the filter manufacturers place a label or plate on the filter tank that lists all the different filter sizes for that particular model. Then they put a check mark or punch out a hole next to the actual filter size. That is, in theory. I hear from many customer that there is no mark or it has worn off over time. There could also be no readable part numbers on the grids and cartridges themselves, leading to a good deal of confusion.

The easiest solution in this case is to measure the actual media. So for DE grids, you would measure the length and width of the full and the partial grids. Most DE filters have seven full grids that are the same size and one partial (shorter) grid. For cartridges, measure the length, the outside diameter of the cartridge, and the diameter of the hole. Often people don’t want to take the extra step of opening the filter to get these dimensions and they take a guess at the correct size. This makes for an awful lot of returns during pool season so I highly recommend doing it right the first time.

Replacing sand can also present a challenge or two. The main question being “how much sand do I need for my filter?” This will be in your owner’s manual but if yours has gone missing, feel free to contact us here as we have specs on many filter models. The manufacturer can also be a resource for the proper sand amount for older, more obscure filters. You will want to check on the recommended sand type as well which is typically #20 or #30 silica sand but does vary per manufacturer.

If you’ve been a pool owner for any length of time, you will not be surprised if you run into other filter problems not covered here. As customers often tell me, “It’s always something!” But rest assured, we’re happy to help you troubleshoot filter problems, find replacement parts, and get you on your way to enjoying that pool.

Leave a Reply